Industries

Aerospace & Defense

Our aerospace experts are ready to lead your next project.

FlexFoil™ Retrofit on a Gulfstream III

In collaboration with NASA and the Air Force Research Lab (AFRL), FlexSys developed the Adaptive Compliant Trailing Edge (ACTE) system to test the efficacy of flexible trailing edges. The system—which replaced traditional high-lift flaps—utilized seamless, morphing structures as the primary control surface. Testing demonstrated reduced drag and aircraft noise.

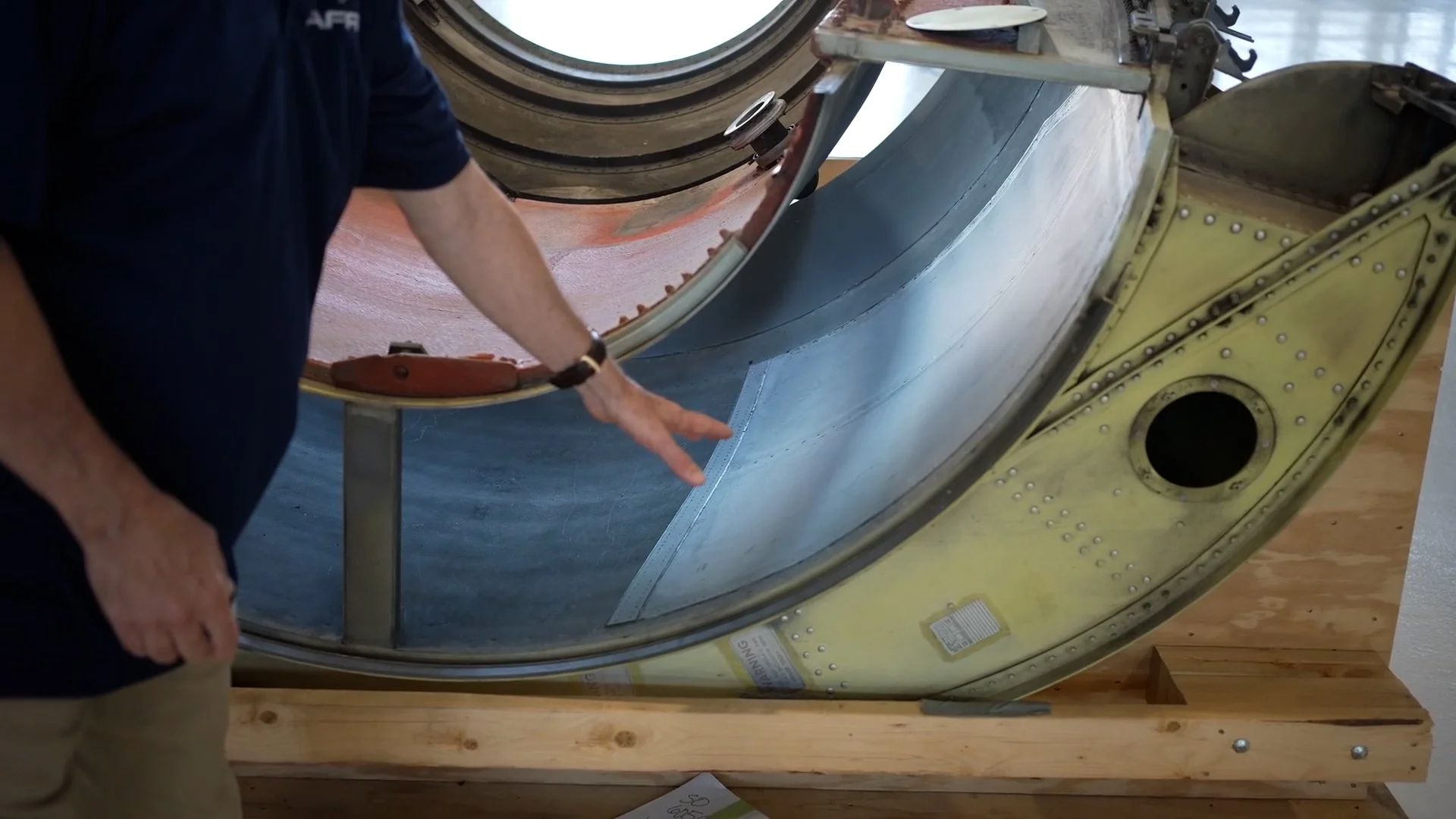

Aircraft Fan Duct Repair

FlexSys designed a solution to standardize fan duct repairs, extending the functional life of the aircraft. This repair also created a smoother surface than the previous repair method, improving aerodynamic performance.

Wing With Morphing Flaps

As part of a joint venture, FlexSys worked with Aviation Partners to construct a demonstration wing that featured morphing control surfaces and a seamless winglet. This demonstration article displays one application of FlexFoil™, which can used in combination with most standard aerospace materials.

Contact us to learn more about aerospace solutions.

Automotive

Solve your next automotive challenge with ideas that go beyond.

Flexible Wiper Technology

To meet safety requirements for sales to the general public, the Aston Martin Valkyrie needed to include a windshield wiper. The vehicle’s curved windshield proved to be an impossible challenge for other vendors. FlexSys overcame this challenge by designing a twisting, carbon fiber blade that stays in contact with the windshield at all times—even at 120 miles per hour.

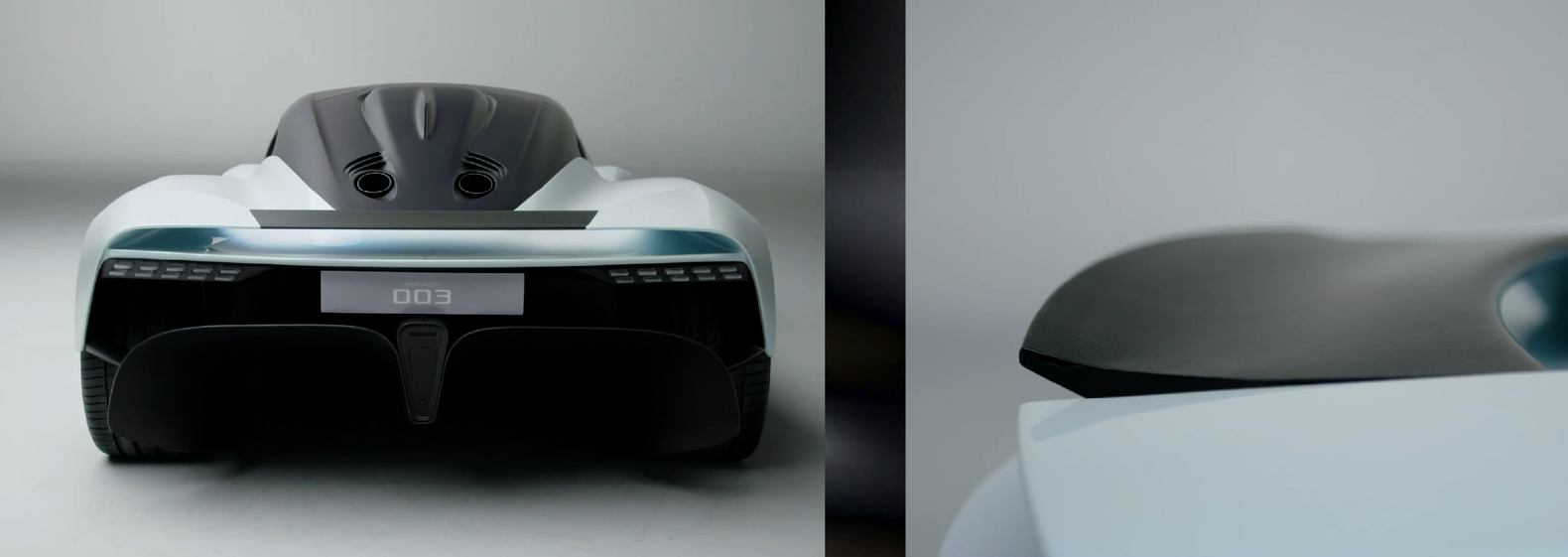

Seamless Aerodynamic Performance

FlexSys worked with Aston Martin to design a rear wing for the AM-RB 003 concept vehicle, which debuted at Geneva Motor Show. The seamless design of the rear wing eliminated the turbulence and drag that are normally present with traditional rear wings. The design resulted in enhanced efficiency and reduced wind noise.

Contact us for creative answers.